| Model | CSL-800 peanut thresher |

| Dimension(mm) | 1440*700*1620 |

| Weight(kg) | 200 |

| Matched power(Hp) | 8 |

| capacity(kg/h) | 600-800 |

| cleaning rate(%) | 98 |

| Filter structure | Specific gravity screen + dust removal system |

| Impurity rate(%) | 3% |

| Loss rate(%) | 0.5 |

| function | peanut skin shelling |

| Ambient temperature(℃) | 5-40 |

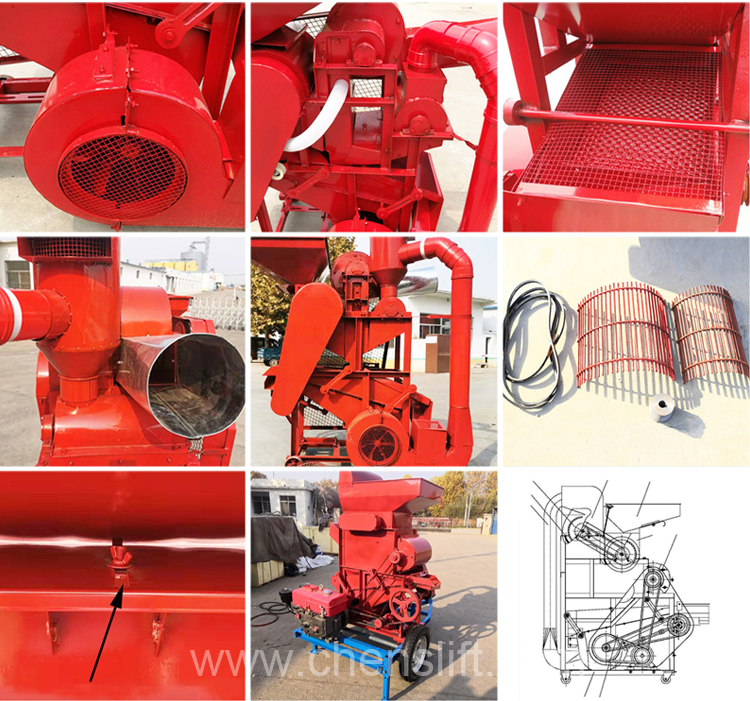

Advantage: 1. Cleaning fan, the pods that have not fallen off are sent to the re-offering device through the cleaning fan for a second time, and the output is increased by 10%; the combination of the vibrating screen and the cleaning fan makes the separation more clean; 2. The vacuuming device removes the dust in the working sieve, and the details show high quality; 3. Specific gravity separation sieve, which can screen out different peanut qualities 4. The dust removal fan can put a pocket on the fan to make the working environment cleaner; 5. Re-exiting pipeline, high airtight performance, no air leakage after long-term use 6. Accessories, provide 2 sets of screens, according to the particle size, suitable for different varieties of peanuts. 7. The feed port switch needs to be closed before work, and can be opened to about 4cm after normal work. 8. It can be customized to add mobile wheels and diesel engine frames according to demand.

Advantage: 1. Cleaning fan, the pods that have not fallen off are sent to the re-offering device through the cleaning fan for a second time, and the output is increased by 10%; the combination of the vibrating screen and the cleaning fan makes the separation more clean; 2. The vacuuming device removes the dust in the working sieve, and the details show high quality; 3. Specific gravity separation sieve, which can screen out different peanut qualities 4. The dust removal fan can put a pocket on the fan to make the working environment cleaner; 5. Re-exiting pipeline, high airtight performance, no air leakage after long-term use 6. Accessories, provide 2 sets of screens, according to the particle size, suitable for different varieties of peanuts. 7. The feed port switch needs to be closed before work, and can be opened to about 4cm after normal work. 8. It can be customized to add mobile wheels and diesel engine frames according to demand.